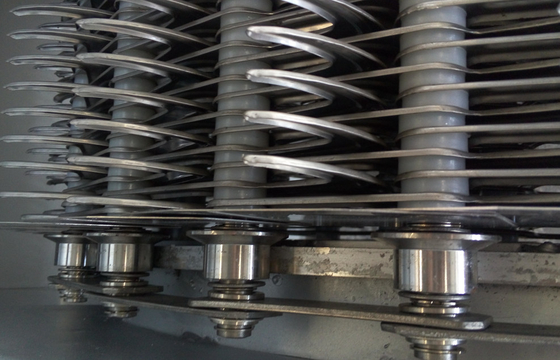

Mechanical Wastewater Bar Screen Grilling Screen Machine CFH Rotary Grille

Product Details:

| Place of Origin: | China |

| Brand Name: | CHENENG |

| Certification: | CE/ISO |

| Model Number: | CFH |

Payment & Shipping Terms:

| Minimum Order Quantity: | 1pcs |

|---|---|

| Price: | negotiation |

| Packaging Details: | nude packing, bulk packed in wooden cases |

| Delivery Time: | 15 working days after received your payment |

| Supply Ability: | 20 pcs per month |

|

Detail Information |

|||

| Product Name: | Rotary Grille | Application: | Water Treatment |

|---|---|---|---|

| Material: | CS Or SS | Standard: | ISO |

| Structure: | Compact Connection | ||

| High Light: | water purification screening,rotary bar screen |

||

Product Description

Mechanical bar screen/grilling screen machine/CFH Rotary Grille

Application

■ It is applied to process urban sewage, as the inlet in the running water industry and power plant, and also process the sewage from the textile, food processing, paper-making and leather industries

The pre-screening equipment in the processing technology.

Advantages

■ The biggest advantages of the equipment are high automation degree, high separation efficiency, little power consumption, absence of noise, good anti-corrosion performance;

■ The operation spacing of the equipment can be easily adjusted in accordance with customer demands to realize the periodic operation;

■ The equipment has strong self-cleaning capacity, and has no blocking phenomenon, so there is small daily maintenance workload;

|

Model Parameter |

CFH- 500 |

CFH- 600 |

CFH- 700 |

CFH- 800 |

CFH- 900 |

CFH- 1000 |

CFH- 1100 |

CFH- 1200 |

CFH- 1300 |

CFH- 1400 |

CFH- 1500 |

||||||

| Equipment Breadth B (mm) | 500 | 600 | 700 | 800 | 900 | 1000 | 1100 | 1200 | 1300 | 1400 | 1500 | ||||||

| Channel Breadth B1 (mm) | B+100 | ||||||||||||||||

| Effective Grille Breadth B2 (mm) | B-157 | ||||||||||||||||

| Bolt Pitch B3 (mm) | B+200 | ||||||||||||||||

| Total Equipment Breadth B4 (mm) | B+350 | ||||||||||||||||

| Tooth Clearance B (min) |

t=10 0 |

1≤b≤10 | |||||||||||||||

|

t=15 0 |

10<b≤50 | ||||||||||||||||

| Installation Angle α (º) | 60-85 | ||||||||||||||||

| Channel Height H (mm) | 800-12000 | ||||||||||||||||

| Discharge Outlet Height H1 (mm) | 60-1200 | ||||||||||||||||

| Total Equipment Height H2 | H+H1+1500 | ||||||||||||||||

| Rear-cabinet Mount Height H3 (mm) |

t=10 0 |

≈1000 | |||||||||||||||

|

t=15 0 |

=1100 | ||||||||||||||||

| Tooth Velocity V (m/min) | =2.1 | ||||||||||||||||

| Motor Power N (kw) | 0.55-1.1 | 0.75-1.5 | 1.1-1.2 | 1.5-3.0 | |||||||||||||

| Water Head Loss (mm) | ≤20 (Without blocking) | ||||||||||||||||

| Civil Engineering Load | P1(KN) | 20 | 25 | ||||||||||||||

| P2(KN) | 8 | 10 | |||||||||||||||

| △P(KN) | 1.5 | 2.0 | |||||||||||||||

![]()